"Plastiform's products have enabled us to carry out high quality non-destructive testing on aircraft parts, saving time and production for our customers."

P.S. @Liebherr Aerospace

Use Plastiform.

CONTROL YOUR PARTS WITH COST EFFICIENCY, FASTER AND PRECISELY.

By using Plastiform products, you can control uncontrollable parts in less than 10 minutes and for less than $5, all without destroying them!

Trusted and used by top brands around the world

Precision 3D replicas for Quality Control

We avoid destructive testing so you can deliver and maintain parts during their whole lifecycle.

Plastiforms are used to control part dimensions or surfaces finishing at every stage of a part.

- Systematic controls during production

- Systematic controls at reception

- Recurring wear evaluations

- No disassembly required. Keep the part where it is, just measure its impression.

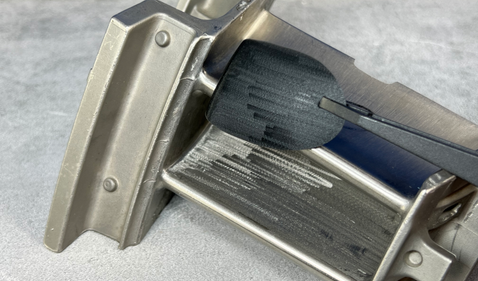

Internal & External Dimensional Controls

Ever wondered how to measure the inside of a part without having to damage it? Plastiform offers a way to measure every shape of your part and avoid up to 98% destructive controls.

Get more details

Indirect Roughness Controls

Plastiform replicas are able to reproduce a surface conditions with a resolution of 0,001 µm. Measure the roughness of your surface directly on the impression with or without contact.

Get more details

Visual Surface Finish

Plastiform Products are suitable for the creation of custom protective mold able to protect your parts in batch against all kinds of surface treatments.

Get more details

Not sure which product best fits your needs ?

Try them all with the Complete Solution Case. This case contains all required accessories to use Plastiform and each product of the main range.

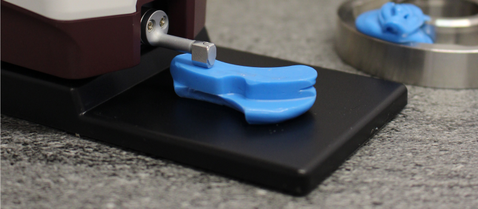

Simplify Measurement with the Double Blade Cutter

This cutter forged by hand allows you to make sections that are easy to position and measure on optical measurement machine.

Don’t take our words for it.

There is thousands of people using Plastiform every single day.

"The Plastiform worked very well. We find it helpful to capture the condition of inaccessible features on injection molded parts and tooling. I like the large variety of your products that are not available from competitors. The different viscosities and hardness levels are very helpful."

A.E. @Stone Plastics"We’ve been super happy with the set we ordered. We’ve been able to examine our internal threads on our vision system which has been really helpful for our QC team."

S.R. @EnervenueGet the latest Plastiform insights

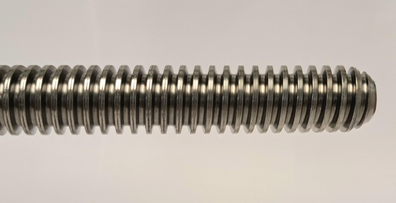

ACME Threads – The Complete Guide

Acme threads are very common in all sorts of everyday machinery. You’ll encounter them in many different types of machines. However, the specific reason why that distinctive 29° flank angle appears so consistently in engineering blueprints is not that easy to find. Short answer : This geometry is not a… <a href="https://www.plastiform.info/en/blog/engineering/acme-threads-the-complete-guide/" class="read-more">Read More</a>

API Thread Standards – Complete Overview 2025

Ever wondered why the American Petroleum Institute, or API, specs even came to be? Well, picture this: You’ve got a massive steel pipe, diving down through the seabed, snaking several kilometers underground, and then, eventually, carrying highly pressurized oil and gas all the way back up to the surface. <a href="https://www.plastiform.info/en/blog/engineering/api-thread-standards-complete-overview/" class="read-more">Read More</a>

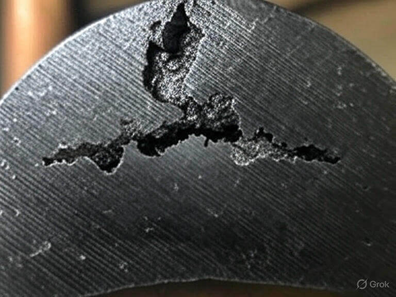

Shrinkage in Metal Casting and How to Prevent it?

Shrinkage in Metal Casting is a constant companion in our world of mechanical engineering, specifically when we’re dealing with cast metals. It’s a sneaky phenomenon that can turn a perfectly designed component into something… Well, not quite right. That moment when you realize the final piece isn’t quite the dimensions… <a href="https://www.plastiform.info/en/blog/engineering/shrinkage-in-metal-casting-and-how-to-prevent-it/" class="read-more">Read More</a>