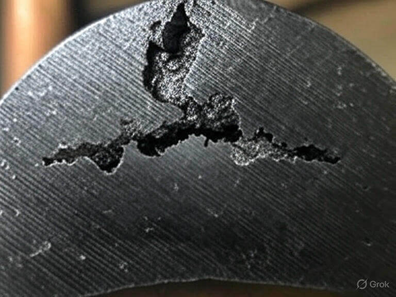

Shrinkage in Metal Casting and How to Prevent it?

Shrinkage in Metal Casting is a constant companion in our world of mechanical engineering, specifically when we’re dealing with cast metals.It’s a sneaky phenomenon that can turn a perfectly designed component into something…Well, not quite right. That moment when you realize the final piece isn’t quite the dimensions you meticulously planned. <a href="https://www.plastiform.info/en/blog/engineering/shrinkage-in-metal-casting-and-how-to-prevent-it/" class="read-more">Read More</a>