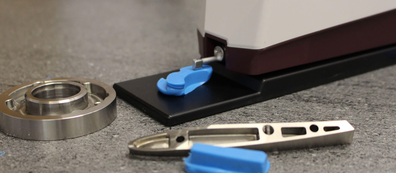

A profile projector, also known as an optical comparator, is a precision measuring instrument widely used in metrology and quality control.

This advanced optical device projects an enlarged shadow of the part being measured onto a screen, allowing the operator to perform accurate measurements with ease.

While the principle is similar to that of shadow puppetry, profile projectors remain highly effective and widely used in modern manufacturing.

Plastiform offers products specifically designed for use with profile projectors, catering to the needs of many of our customers. But how exactly does a profile projector work?

Table of Contents

Evolution of Profile Projectors (Optical Comparators)

Since they were first invented, profile projectors have improved a lot to meet the needs of quality control.

Today’s quality inspectors need profile projectors that are efficient, stable, and easy to use.

Modern profile projectors have many useful features that are simple to set up. They’ve come a long way from the early models, but the basic idea is still the same.

What makes modern Profile Projectors special?

These days, optical measuring tools like profile projectors are some of the most reliable measuring devices out there.

Manufacturers make sure their profile projectors have up-to-date technology, including:

- Guidance systems and laser pointers to help control the machine easily.

- Built-in software to help operators take measurements and ensure they’re very accurate.

- Systems that can position parts quickly.

These profile projectors are made with high-quality materials. For example, the Sylvac Visio 200 profile projector has a base made of granite.

Granite is heavy and very stable, which helps the machine stay in place and ensures the measuring surface lasts a long time.

Lighting Options in Modern Profile Projectors and Optical Comparators

Being able to change the lighting on a profile projector or optical comparator helps you adapt the machine to different measurement needs.

There are two main types of lighting:

- Diascopic lighting (light from below): This helps measure outlines and check transparent parts.

- Coaxial episcopic lighting (light from above): This works well for large magnifications, like checking blind holes or shiny parts.

On newer profile projectors, it’s easy to adjust the lighting. For example, the Visio 200 we use is sturdy and lets us switch lighting modes right from the computer.

To measure Plastiform impressions, it is often necessary to use diascopic lighting (backlight – the light below). It is more suitable for the measurement process we have established.

Profile projector and Plastiform, how does it work ?

Plastiform is a special technology for taking impressions of parts to check their size or surface finish.

This technology is specially made for quality control in the industry. More and more people in the industry are using it because it’s so good at what it does.

Plastiform, what is it? Why use it with a profile projector?

The technology is very simple to use. Plastiforms are polymers originally in two components. Mixing the two components together initiates a chemical reaction: polymerization.

This chemical reaction allows the product to harden and capture the properties of the part to be measured.

Cured products have several properties that are very interesting for quality control:

- Easy to extract: some products are very flexible, so it is possible to extract them from the part without damaging either the part or the impression.

- Shape memory: pulling on the product does not deform the impression; it always returns to its original state.

- No dimensional shrinkage: During polymerization, there is no dimensional shrinkage. The impression is accurate to the micrometer.

- The impressions can be cut: You can easily slice the impression.

It is this last property that makes Plastiform a technology very suitable for profile projectors!

Not only are you able to inspect areas that are inaccessible to your measuring instruments, but you can also cut a two-dimensional profile of the impression, without damaging it, to inspect it by projection.

Preparing a Plastiform impression for a profile projector

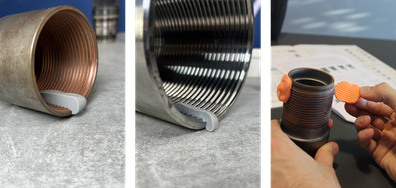

When you extract your impression, it will be three-dimensional: the exact negative of your part.

Creating a two-dimensional profile slice may seem challenging at first, but don’t worry – we’ve considered everything!

To address this need, Plastiform has developed a custom-made Double Blade Cutter with two parallel, hand-sharpened blades.

This cutter, along with its cutting guide, allows you to create a transverse slice of the impression in a single motion. Here’s what the result looks like:

As you can see, the cutter produces a perfect slice of the impression.

This slice is much easier to analyze on a profile projector than the full replica would have been.

With backlighting, simply place the impression slice flat on the stage of the profile projector, and you can proceed with your measurements.

Conclusion

The profile projector is one of the most widely used measuring devices in industry, making its technology highly suitable for quality control applications.

With a modern profile projector, you can easily adapt your inspection environment using all the available options.

To measure a Plastiform impression, you will typically need to use a profile projector or optical comparator.

These machines allow for more precise inspection than contact measurement machines and generally offer a good price-to-performance ratio.

By following the process developed by Plastiform, you can create your impressions and then slice them with the Double Blade Cutter.

This provides you with a cross-section of the negative of your part. The slices made with the Plastiform Cutter are very easy to examine using a profile projector, especially when using backlighting.