Plastiform products are frequently used by OCTG* (Oil Country Tubular Goods) manufacturers to carry out the control and inspection of API threads, tubings and casings.

* OCTG is a specific family of steel pipe designed for oil drilling, extraction and transportation of oil and natural gas.

Table of Contents

Introduction

Function of threads

Threads on oil well tubular products serve two purposes :

- Assemble tubing that must withstand high stresses

- Avoid leakage or entry of fluids into the different columns

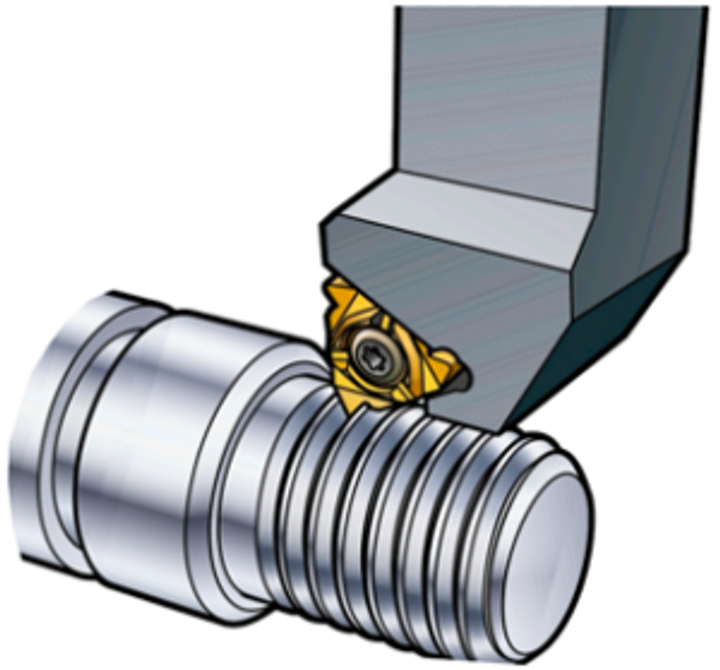

When machining a thread, the tool undergoes wear and, if the wear is excessive, the resulting thread will show a series of surface defects and will be out of tolerance. Consequently, the resistance of the thread to mechanical forces will be reduced.

Thread inspection

The threaded ends must be checked dimensionally at the plant where it is manufactured (this is where Plastiform impressions usually come in), but also inspected visually in the field.

- Inspection at the plant is usually done by statistical sampling to control the process.

- Field inspection is usually done visually to check wear and defects.

API and Premium Threads

There are two main types of Premium connections :

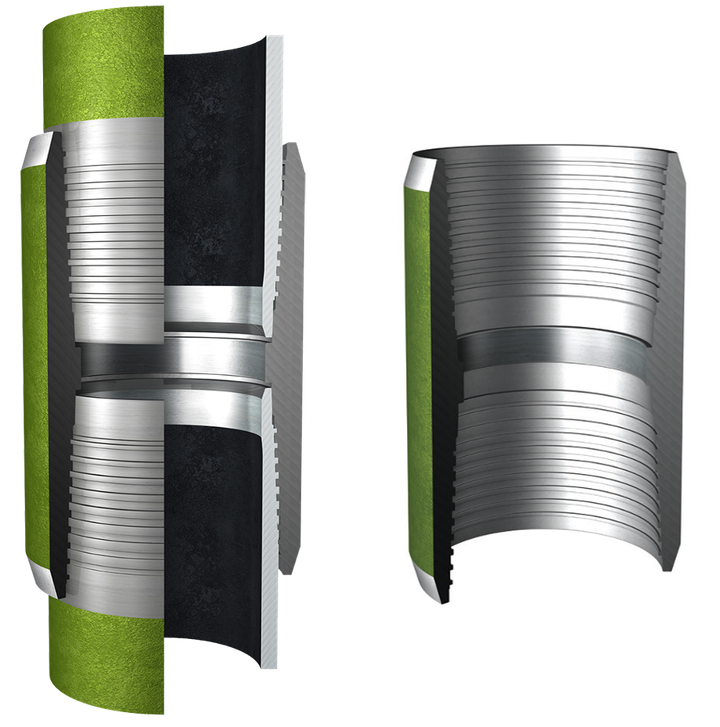

Coupled connections

The most typical fittings used in oil and gas wells are threaded and coupled fittings, in which two pipes are joined by a third component called Couplings.

Integral connections

They connect two pipes without a third element or couplings. In this case, the tube has an external thread (pin) at one end and an internal thread (box) at the other end.

And this is a full connection :

Inspection using precision impression

Mold inspection with Plastiform

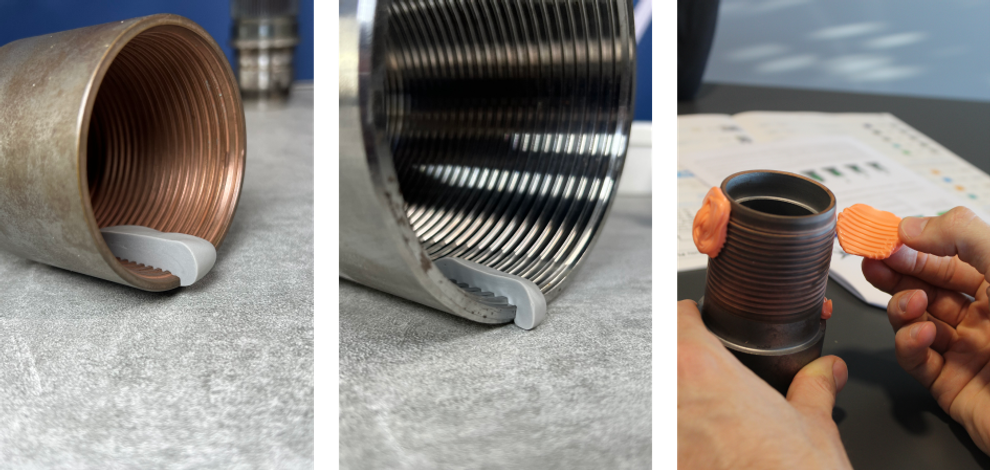

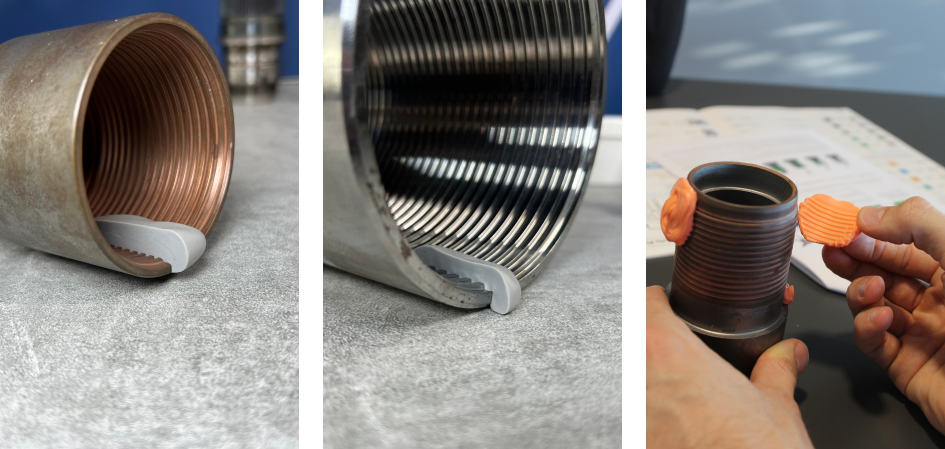

Plastiform impressions are precision molds that are used to indirectly evaluate the shape of Premium threads.

These impressions, made in less than 6 minutes, reproduce dimensions with micron-level accuracy. They are used to inspect external (Pin) and internal (Box) threads for both pipes and couplings.

Plastiform offers two application systems :

- by hand with two-component Malleable Putty

- by gun injection with the bi-component Cartridge system

The impression is used in the factory by the manufacturer, and in the field for visual inspection of the thread.

Inspection procedure with Plastiform – In-plant control

1 – Cleaning and degreasing of the surface

Using a degreaser validated for Plastiform, clean the surface perfectly.

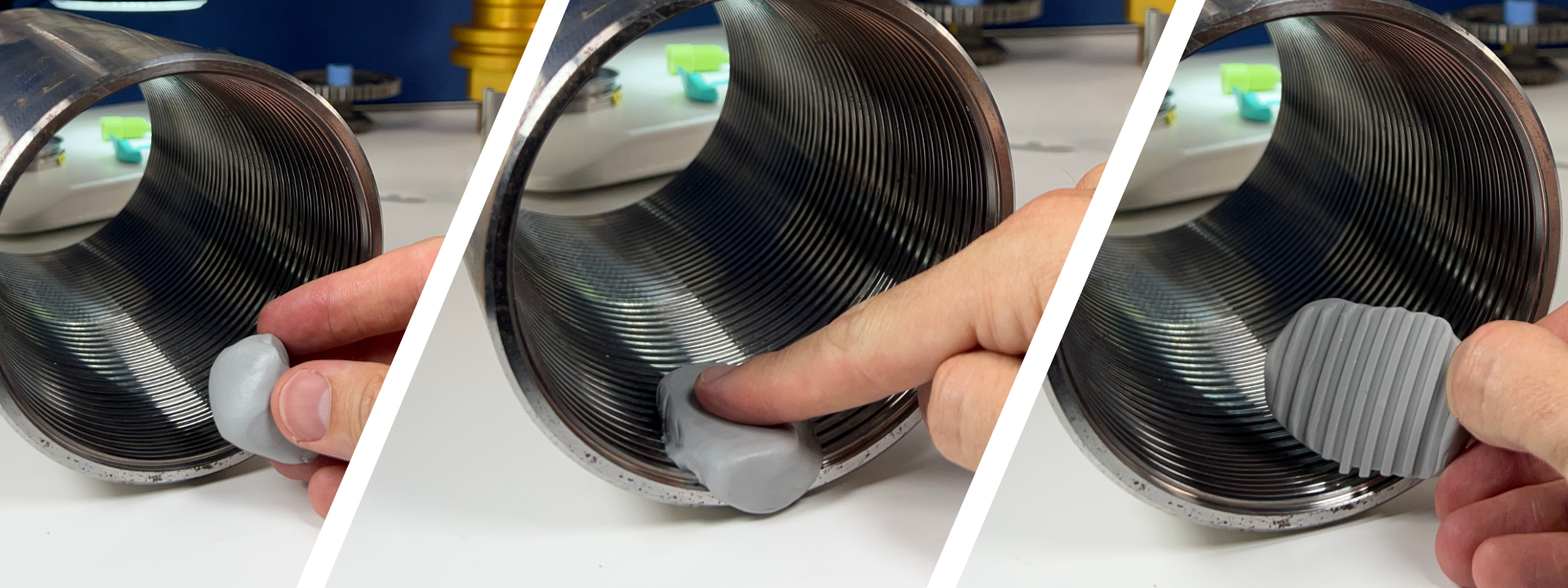

2 – Making the impression

Follow the instructions for use and the technical data sheet to apply Plastiform, and wait the indicated time before removing the impression.

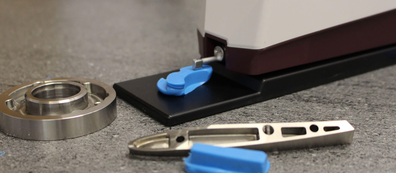

3 – Cutting the impression with the Double Blade Cutter

Cut the Plastiform impression with the Double Blade Cutter to obtain a slice that can be easily inspected on a measuring instrument.

4 – Controlling the impression

The profile thus obtained is directly inspected and measured on an optical measuring instrument (profile projector or optical microscope).

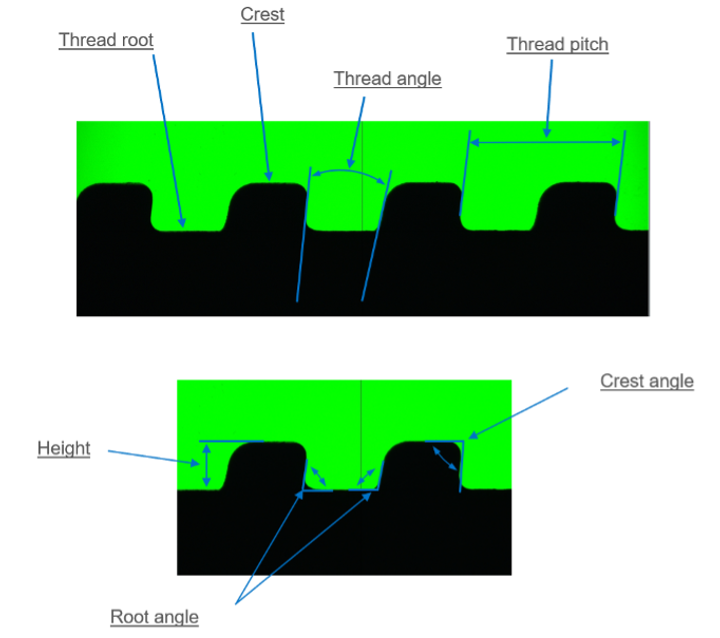

5 – Controlled features

The impressions allow to check a large number of elements on the API Premium threads, the seal and the shoulder :

- Crest angle

- Thread pitch

- Thread height

- Thread angle

- thread root angle

- Dimensions of the seal and the shoulder

Field inspection with Plastiform

Visual Thread Inspection (VTI)

It is performed to evaluate the condition of the thread (Pin and Box) of the tube or couplings. This is to determine if repairs need to be made, or if the tube becomes unusable.

Plastiform impressions allow to reproduce and quantify the wear of threads and prevent some of the following risks:

- Galling

- Scratches

- Burrs

- Mashed threads

- Rust

- Corrosion

- Pitting

References

Plastiform impression inspection is used by the largest suppliers of OCTG products:

- Tenaris

- Vallourec

- Hunting Energy Services

- NOV

- Weatherford

- Voestalpine Tubulars

- BakerHughes

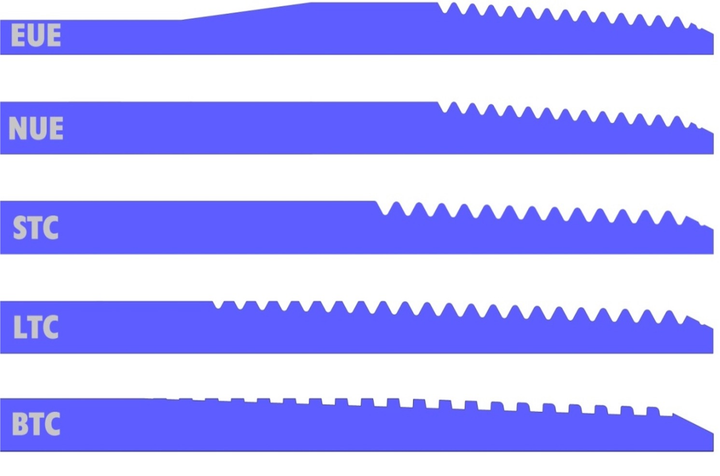

Plastiform provides fast and accurate solutions for testing oilfield drill pipes (tubing and casing) to API specifications:

- EUE : External Upset Tubing

- NUE : Non-Upset Tubing

- BTC : Buttress Casing

- LTC : Long Thread Casing

- STC : Short Thread Casing